Thermochromic materials—substances that change color in response to temperature variations—offer a promising avenue for advancements in electrical inspections. Electrical systems, ranging from household wiring to complex industrial networks, require regular maintenance and inspection to ensure safety and functionality. Traditional methods of electrical inspection, while effective, can be enhanced by integrating thermochromic technology.

Principles of Thermochromics

Thermochromism refers to the ability of a substance to change color due to a change in temperature. This property is typically exhibited by materials that undergo a chemical or physical transformation when heated.

Applications in Electrical Inspections

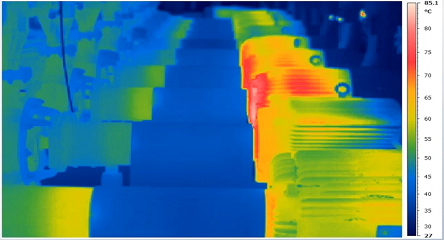

Electrical systems generate heat during operation, with excess heat often indicating issues such as overloading, poor connections, or failing components. Thermochromic products, such as cable clips, paints, and labels, can be applied to electrical components, cables, and connections to provide a visual indication of temperature variations, enabling inspectors to quickly identify and address potential problems.

Cable and Wiring Inspections:

Thermochromic products can be applied to cables and wires. Under normal operating conditions, these materials would display a specific color. If a wire or cable begins to overheat, the thermochromic material would change color, signaling the presence of an abnormal condition. This allows inspectors to pinpoint problematic areas with a simple visual inspection.

Electrical Component Monitoring:

Electrical components such as circuit breakers, transformers, and connectors can also benefit from thermochromic applications. By applying thermochromic products to these components, inspectors can visually monitor the temperature of critical parts. This real-time monitoring can help in identifying overheating components before they fail, thus preventing potential hazards and unscheduled outages.

Industrial Applications:

In industrial settings, where electrical systems are often more complex and critical, thermochromic materials can be integrated into safety protocols. For example, thermochromic cable clips and labels can be attached to high-voltage equipment to provide a visual alert if temperatures exceed safe operating limits. This adds an extra layer of safety, reducing the risk of electrical fires and equipment damage.

Benefits of Using Thermochromics

Cost-Effectiveness:

One of the most significant advantages of using thermochromic materials in electrical inspections is cost-effectiveness. Thermochromic paints, clips, and labels are relatively inexpensive. This makes them accessible for a wide range of applications, from residential to industrial settings.

Ease of Use:

Thermochromic materials provide a simple, intuitive way to monitor temperatures 24/7. Color changes are easy to interpret, requiring minimal training for inspectors. This ease of use enhances the efficiency of inspections, allowing for quick identification and resolution of issues.

Real-Time Monitoring:

Thermochromic materials enable continuous, real-time monitoring of electrical systems. This is particularly beneficial in environments where constant vigilance is required, such as in industrial plants or critical infrastructure. Immediate visual feedback on temperature changes can lead to faster response times and reduced downtime.

Non-Intrusive Inspection:

Unlike some traditional inspection methods that may require disassembly or direct contact with components, thermochromic materials allow for non-intrusive inspections. This reduces the risk of damaging sensitive components and minimizes disruption to the electrical system’s operation.

Enhancing Safety:

By providing a clear visual indication of overheating, thermochromic materials can significantly enhance safety. Early detection of thermal anomalies can prevent electrical fires, equipment failures, and potentially hazardous situations, protecting both personnel and property.

Leveraging thermochromic materials for electrical inspections represents a significant advancement in the field of maintenance and safety. The ability of these materials to provide real-time visual feedback on temperature changes offers numerous benefits, including cost-effectiveness, ease of use, and enhanced safety.

For more information on our thermochromic solutions, or to purchase a kit online, please visit https://iriss.com/safe-connect-thermochromic-solutions/.