Gearbox Maintenance

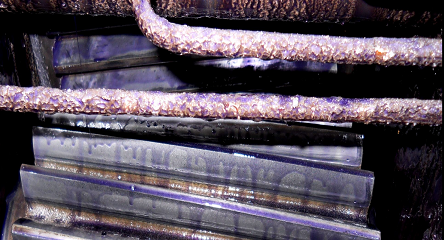

Gear reducers tend to be rugged, durable pieces of equipment, and built-in safety factors protect them against the severity of most applications. However, their performance efficiency and operating life can be diminished greatly without a proper lubrication reliability program. Overlooking the necessity of such a program has led to the failure of many gear reducers.

Proper gearbox maintenance – including a high-quality oil meeting OEM specifications, desiccant breather, and oil sight glass and lever monitor or bottom sediment and water bowl – can significantly improve gear reducer performance as well as the overall health of the equipment and lubricant.

Lubricant Recommendations

LE’s gear lubricants keep gear reducers running efficiently in hundreds of facilities around the world, often lowering costs in the process. To ensure proper lubricant selection, the following should be considered: speed, load, temperature, and operating environment.

Following are suggested enclosed gear lubricants for gear reducers.

R&O Gear Oils

• Monolec R & O Compressor / Turbine Oil

• Multilec Industrial Oil

EP Gear Oils

• Monolec Gear Lubricant

• Duolec Industrial Gear Oil

• Duolec PAG Gear Lubricant

• Duolec Syn Gear Lubricant

• Monolec Syn Gear Oil