About the Author

Aung Zay Yar Min is a degree holder specialized in mechanical engineering. He has 16 years of experience in mechanical maintenance of static and rotating equipment.

READ FULL BIOI. SCOPE OF WORK

I.A BACKGROUND:

5-Star hotel has recently acquired the SPM online vibration monitoring system for 22 units of exhaust fans. This system has been implemented to enhance the monitoring and maintenance of their equipment. SPM offered the convenience of conducting

onsite vibration measurements and provides analysis reports twice for this project. This report comprehensively evaluates the condition of the vibration analysis equipment, utilizing data collected by portable instruments.

I.B TOOLS:

The following instrumentation was used to perform the vibration and bearing

condition measurement:

. EME400: Leonova Emerald (HD Analysis, VIB/SPM HD Expert)

. Condmaster Ruby Software

I.C TEST CONDUCTED:

. Vibration data are collected using Leonova Emerald on site by SPM Service

Engineer

. Vibration data are imported to Condmaster Software for analysis.

I.D MEASUREMENT POINT LAYOUT:

II. VIBRATION SEVERITY & CRITERIA LIMIT

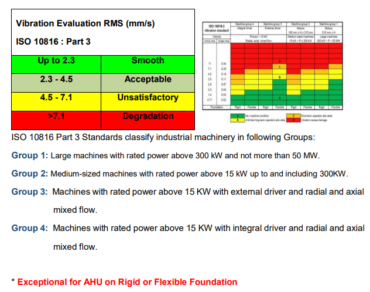

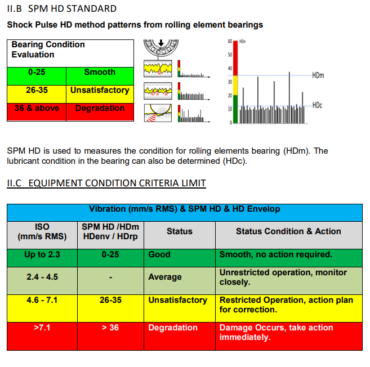

II.A ISO 10816 STANDARD

Vibration measurement is a technique employed to identify and assess the magnitude of vibration in machinery or mechanical systems. It is an important technique in predictive maintenance and can help diagnose faults, especially in the early stages.

By measuring and analyzing vibration levels, maintenance professionals can make informed decisions about repairs and replacements, leading to cost savings and reduced downtime. Vibration measurement can detect various types of machine faults

and abnormalities such as Imbalance, Misalignment, Mechanical Looseness, Bearing Faults, Gear Problems, Resonance and Electrical Faults. The root mean square (RMS) value of vibration velocity, measured in mm/s (or inch/s),

is utilized as a criterion for categorizing machines into four distinct classifications: ‘smooth’, ‘acceptable’, ‘unsatisfactory’, or ‘ Degradation ‘.

IV. CONCLUSION

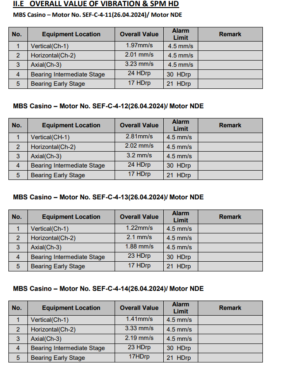

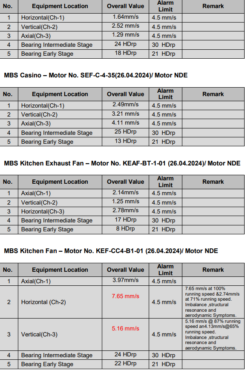

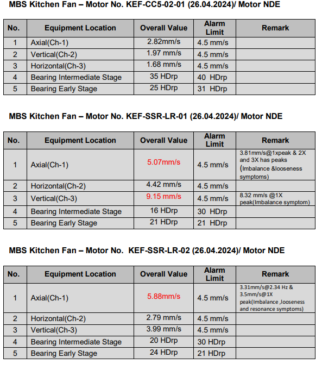

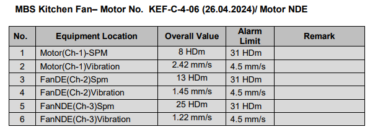

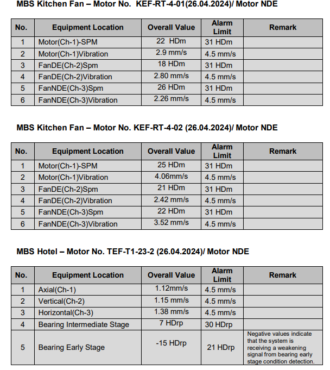

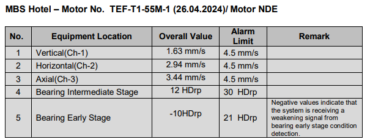

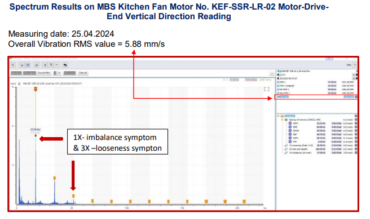

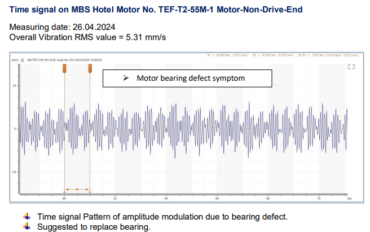

In conclusion, the vibration analysis conducted on the 22 units of exhaust fans has yielded valuable insights into their performance and potential issues. Out of the total units, 17 fans are currently operating within acceptable vibration limits, while 4 fans are experiencing excessive vibrations, as per the ISO 10816-3 standard.

Furthermore, the analysis identified a concerning weakening signal, HDENVF4 of some TEF fans. This issue may be attributed to the mounting of vibration sensors on the fan cover, whereas conventional practice dictates that the sensors should be mounted on the bearing housing for more accurate bearing analysis.

The recorded vibration levels during operation have surpassed the recommended limits outlined in the ISO 10816 Standard. This signifies the existence of excessive vibrations, which can adversely impact the system’s reliability, efficiency, and safety.

The primary findings of the analysis entail the identification of 1X frequencies and symptoms indicative of bearing faults. These factors likely contribute to the elevated vibration levels observed in certain fans. Consequently, it is crucial to address these

underlying mechanical or bearing issues promptly.

However, it is important to acknowledge that the analysis may have certain limitations, such as data availability or system complexity. Therefore, further investigation and analysis may be necessary to gain a comprehensive understanding of the vibration behavior and its underlying causes.

Overall, addressing the excessive vibrations identified in this report will contribute to the enhanced performance, reliability, and longevity of the exhaust fan units.

Aung Zay Yar Min is a degree holder specialized in mechanical engineering. He has 16 years of experience in mechanical maintenance of static and rotating equipment.

READ FULL BIO