White Papers

Selecting Vibration Sensors

Nine Questions to Successfully Identify the Solution to Your Application

Selecting the best accelerometer for a specific predictive maintenance application can be a daunting task – even for the most seasoned walk-around warrior. Sensor manufacturer’s web pages are laden with hundreds, if not thousands, of similar looking tin cans, all for “vibration monitoring”. The selection process can typically be filtered down to a series of nine specific questions. This article will allow you to master the mystery of vibration application engineering. By discovering the answers to the following nine questions, as it applies to your personal application, you will be able to find the best vibration monitoring solution.

Question #1 – What do you want to measure?

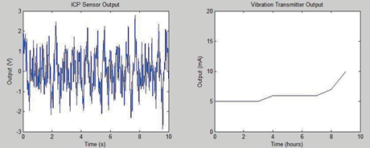

This may seem obvious at first, but stop for a second – what are you actually trying to measure? In other words, what are your goals? What are you actually expecting? What are you going to do with the data? Vibration can be monitored with accelerometers that provide raw vibration data or transmitters which provide the calculated overall RMS (Root Mean Square) vibration. The raw vibration data is useful to analysts because it contains all the information in the vibration signal; the true peak amplitudes and the frequencies of vibration. The overall RMS or peak values are useful to control systems such as PLC, DCS, SCADA, and PI due to a continuous 4-20mA signal. In some applications, customers use both. By determining which of these signals is required for your application, you can significantly narrow your search. Also, are you measuring vibration in acceleration, velocity, or displacement? Have you considered some of today’s industrial sensors are equipped with the ability to output temperature along with vibration? Both ICP® (Integrated Circuit Piezoelectric) accelerometers and 4-20 mA transmitters are available with the temperature output option. Lastly, some applications, such as vertical pumps, are ideally monitored in more than one axis of vibration. Does your application require uni-axial, bi-axial, or tri-axial measurement?

Comparison of ICP® sensor and 4-20 mA transmitter outputs.

- ICP® raw vibration, 4-20 mA transmitter, or both?

- Are you measuring acceleration, velocity, or displacement?

- Do you want to measure temperature?

- Single axis, bi-axial, or tri-axial measurement?

Question #2 – What is the amplitude of vibration?

The maximum amplitude or range of the vibration being measured will determine the range of the sensor that can be used. Typical sensitivities for ICP® accelerometers are 100 mV/g for a standard application (50 g-range) and 500 mV/g for a low frequency or low amplitude application (10 g-range). General industrial applications with 4-20 mA transmitters commonly use a range of 0-1 in/s or 0-2 in/s.

Question #3 – What is the frequency of vibration?

Physical structures and dynamic systems respond differently to varying excitation frequencies – a vibration sensor is no different. Piezoelectric materials, by nature, act as high pass filters and as a result, even the best piezoelectric sensor will have a low-frequency limit near 0.2 Hz. Sensors, acting like a single degree of freedom dynamic system, have natural frequencies. At the natural frequency, the signal is greatly amplified leading to significant change in sensitivity and possible saturation. To combat saturation caused by exciting sensor resonance, most industrial accelerometers have single or double pole RC filters. It is critical to select a sensor with a usable frequency range that includes all frequencies of vibration you are interested in measuring.

Question #4 – What is the temperature of the environment?

Extremely high-temperature applications can pose a threat to the electronics built into ICP® accelerometers and 4-20 mA transmitters. IMI Sensors offers “HT” or high-temperature versions of both ICP® and 4-20 mA sensors. For very high-temperature applications charge mode accelerometers are available. Charge mode accelerometers do not have built-in electronics like ICP® sensors but instead have remotely located charge amplifiers. For ultra-high temperature applications above 500 F, such as gas turbine vibration monitoring, charge mode accelerometers with integral hardline cable are available.

| Temperature | Type of Sensor | Built-In Electronics |

| 185 ºF (85 ºC) | 4-20 mA Transmitter | Yes |

| 250 ºF (121 ºC) | ICP® Accelerometer | Yes |

| 255 ºF (125 ºC) | “HT” 4-20 mA Transmitter | Yes |

| 325 ºF (162 ºC) | “HT” ICP® Accelerometer | Yes |

| 500 ºF (260 ºC) | Charge Accelerometer | No |

| 900 ºF (482 ºC) | Integral Hard-line Charge Accelerometer | No |

Question #5 – Will it be submersed in liquid?

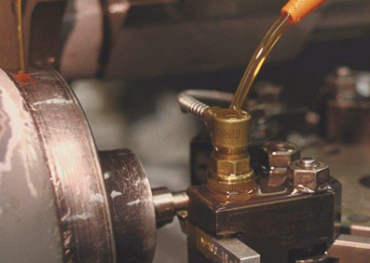

MI’s industrial accelerometers with integral polyurethane cable are completely submersible in liquid for permanent installation to depths corresponding up to 1,000 PSI. For high-pressure applications, it is recommended to pressure test the sensors at pressure for one hour. Applications requiring complete submersion will need integral cable. If the application is not completely submersed but sprayed, such as cutting fluid on machine tools, integral cable is normally required as well.

Question #6 – Will it be exposed to any potentially harmful chemicals or debris?

IMI’s industrial accelerometers are constructed with stainless steel bodies to be corrosion and chemical resistant. If your application is located in an environment with harmful chemicals, consider using PTFE cable with corrosion resistant boot connectors. It is strongly recommended to check a chemical compatibility chart for any suspect chemicals. For cables that may come into contact with debris such as cutting chips or workers’ tools, integral armor jacketed cables offer excellent protection.

IMI 607A61 Swiveler® and armor jacketed cable immersed in cutting oil.

Question #7 – Do you prefer a top exit, side exit, or a low profile Swiveler®

Ultimately, the sensor you select will need to be installed on your equipment in the space available. Sensors are available with top and side exit connectors or integral cables. The geometry of the sensor has little impact on its performance but issues such as space and the maintenance engineer looking for a place to step should be considered. IMI’s patented Swiveler® design is one of the lowest profile industrial accelerometers available; the locknut design allows the sensor to be oriented in any direction prior to installation which is especially favorable when working with integral cable.

Question #8 – Should you use a precision or low-cost sensor?

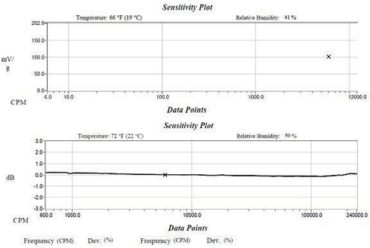

There are two main differences between low cost and precision accelerometers. First, precision accelerometers typically receive a full calibration; that is the sensitivity response is plotted with respect to the usable frequency range. Low-cost accelerometers receive a single point calibration; the sensitivity is shown only at a single frequency. Second, precision accelerometers have tighter tolerances on some specifications such as sensitivity and frequency ranges. For example, a precision accelerometer may have a nominal sensitivity of 100 mV/g ± 5% (95-105mV/g) while a low-cost accelerometer may have a sensitivity of 100 mV/g ± 10% (90- 110mV/g). Customers with data acquisition systems will often normalize the inputs with respect to the actual calibrated sensitivity. This allows a group of low-cost sensors to provide very accurate, repeatable data. Regarding frequency, a precision accelerometer will typically publish frequency ranges where the maximum deviation is 5% while low-cost sensors may only publish a 3-dB frequency band. Keep in mind, a low-cost sensor, although unpublished, may offer excellent frequency response as well.

Comparison of calibration data for a low cost (top) and precision (bottom) accelerometer.

Question #9 – Do you need any special approvals?

Both ICP® accelerometers and 4-20 mA transmitters are available with CSA and ATEX approvals for use in hazardous areas. The type of approval needed should be compared with the published approvals for that sensor to ensure it meets your requirements.

By answering the above nine questions you can greatly narrow your search to the best solution for your application. Keep in mind, some combination of answers may be mutually exclusive, that is a solution for all criteria does not exist. For example, a particular model may not carry the proper ATEX certification for your hazardous area application. Additionally, very specialized applications may have other considerations than those listed above. If you have any questions about your application, please do not hesitate to contact myself or another IMI application engineer.

________________________________________________________________________________________________

1 Accelerometers are vibration transducers that measure acceleration. They are most commonly piezoelectric sensors and provide dynamic vibration signal. Power supplies and data acquisition systems are needed to collect data.

2 Predictive Maintenance, as opposed to scheduled preventative maintenance, attempts to determine and quantify the health of machinery so that maintenance resources can be used more efficiently.

3 Raw Vibration Data, also known as the raw time waveform, is the complete time history of the signal associated with vibration. This data cannot easily be deciphered without the use of a data acquisition system.

4 Vibration Transmitters, as opposed to ICP® accelerometers, are loop powered 4-20 mA output sensors. These are most commonly used for vibration monitoring with a control system due to the continuous 4-20 mA signal requiring little processing. 4-20 mA transmitter outputs are typically related to the RMS or Calculated Peak value of the vibration signal.

5 RMS (Root Mean Square) is used in electrical engineering to determine the average power. For vibration diagnostics, the RMS value of raw vibration signal indicates the average level of vibration and is most commonly used for trending changes over time.

6 True Peak, as opposed to peak or calculated peak, is the actual maximum level of vibration that has occurred within a set of data. This is not to be confused with Calculated Peak which is calculated by RMS*(1.414)

7 ICP® (Integrated Circuit Piezoelectric), also known as IEPE (Integrated Electronics Piezoelectric), sensors have built-in charge amplifiers. As opposed to charge mode accelerometers which require charge amplifiers and have a high impedance signals susceptible to noise, ICP® accelerometers have low impedance low noise signals and can be used with very long cables.

8 Sensitivity of a sensor is the relationship between the electrical output to the mechanical input. Sensitivity for vibration sensors is typically in mV/g for accelerometers and mV/IPS for velocity sensors.

9 Filters are used to attenuate the signal above or below a certain frequency. High pass filters allow higher frequencies to pass through while attenuating lower frequencies. Low pass filters, which are typically used to counteract saturation due to resonance, allow lower frequencies to pass through while attenuating the higher ones.

10 Natural Frequency or Resonant Frequency is the frequency at which a dynamic system naturally vibrates when put into motion. The natural frequency is a function of mass and stiffness of the system. The natural frequency increases with increasing stiffness and decreases with increasing mass. In vibration monitoring, the natural frequency affects the usable range of the sensor.

11 Saturation is a condition in which the sensor has become overloaded and signal clipping occurs. Saturation is caused by using a sensor with a range too low or high-frequency energy (HFE).

12 Charge Mode Accelerometers, unlike ICP®, have external charge amplifiers. Although they are more susceptible to noise, charge mode accelerometers are used in high-temperature applications that would otherwise destroy the electronics of the charge amplifier

Accelerometer vibration sensor transmitter output 4 to 20ma calculate Gram weight signal guidelines please

how’s this Industrial Grade 3-axis MEMS Vibration Sensor with ±16g Range from ncd.io https://store.ncd.io/product/smart-industrial-iot-wireless-vibration-temperature-sensor/

I find this interesting but not sure will that be right choose to buy? Would you suggest to buy?