Two Minute Tips

The Art of Bearing Failure Analysis

Bearing failure analysis is an “art”, but not all who does the bearing failure analysis is an “artist”. While I was conducting a bearing failure analysis of a large size spherical roller used in a crushing application, moisture corrosion was the main reason for the bearings to fail, and the customer was not in agreement since the seals used to protect the bearings from water contamination were found to be in good conditions without damages.

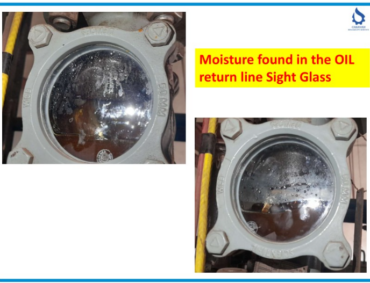

When I did a complete analysis including the oil lubrication systems and breathers fixed on to the bearing housings, I found water/moisture presence in the oil return line coming directly from the bearing housing and the air breathers used for bearing housing were fully BLOCKED.

The customer was convinced in our bearing failure analysis and accepted to implement our recommendations to improve the bearing performance and increase service life.

What triggers the analysis?

Slow speed monitoring of bearing running with oil circulation systems is very tricky and best method is oil sample analysis to check the bearing conditions. Based on oil analysis decisions was taken to replace bearing and conduct analysis.