About the Author

Stan Riddle joined Acoem USA in 2008. He has over 35 years experience in aligning industrial machinery. Stan received his AAS Degree in Machinist Technology from Surry Community College in Dobson, NC, and also holds a diploma in Industrial Systems Technology from Forsyth Technical Community College in Winston-Salem, NC, where he was also an instructor in the program.

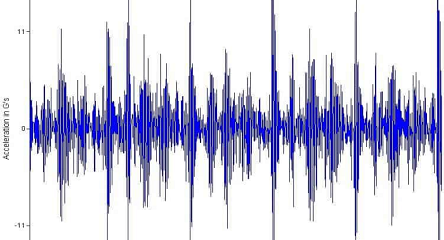

Stan began his maintenance career working as a machinist and millwright for companies such as Weyerhaeuser, R.J. Reynolds, and Tyco Electronics. He also has over 25 years experience in Predictive Technologies, such as vibration analysis, thermography, oil analysis, and ultrasonic inspection. He is a certified Level III Vibration Analyst with the Vibration Institute, and is a Past Chairman and Board Member of the Piedmont Chapter.

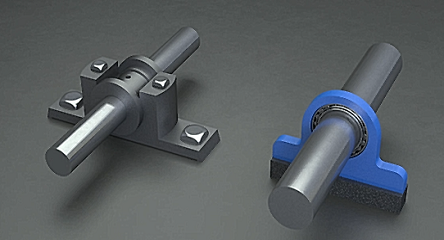

What if i have a situation where both coupling doesn’t have reasonable space to place the laser head such that the only space available on both ends have different diameter? Will laser still be applicable? if it will be, what will be its shortcoming?

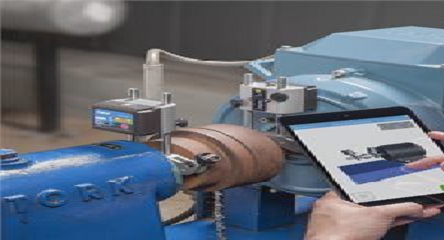

As long as the laser can receive the beam, you should be OK. It doesn’t matter if the laser is mounted onto the shaft or the hub, or one on each. The system will find the center of rotation of the shafts.