A five second Emax Power Test can give you three phase impedance measurements to flag or clear the stator fault zone. Although standard caution setpoints exist for impedance imbalance it is important to remember these alarms are based on a loaded motor. Unloaded or lightly loaded motors will produce higher impedance imbalances and similar loading from history should be used for comparison.

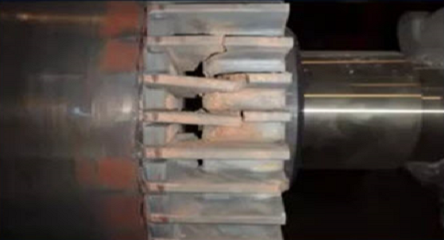

In less than a minute the Emax Rotor Eval and Eccentricity tests produce time domain and spectrum graphs to identify anomalies with the rotor and airgap. Steady state loading is a primary interest with these tests in that a varying load will smear the spectrum plot making the data difficult to analyze. Analysts prefer heavier loads, due to the higher slip increasing the stress on potentially cracked or broken rotor bars. However, don’t be afraid of light loads for comparison to previous tests at similar loading.

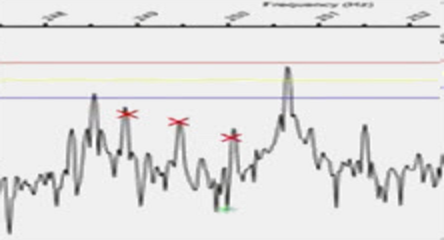

Finally, we shift our focus to the machine train because as electricians often say, “It’s not always the motor.” Many machine train anomalies reflect directly onto the power being fed to the motor and can be seen clearly on the Emax Current Demodulation test. Fan blades, gears, belts, etc., can be identified and marked with band alarms for comparison to historical readings on a convenient waterfall plot. Default band alarms for these shaft line components do not exist so talk to your vendor to discuss recommended changes from baseline to establish your band alarms. Discussing amplitude changes in machine train frequencies with the vibration department at your facility will allow for cross technology verification of possible anomalies and more accurate asset health assignments.

To view a video discussing Troubleshooting for electric motor reliability go to https://www.youtube.com/watch?v=4ACW-AZddtQ .