About the Author

He was graduated from Universitas Islam Indonesia, a well known reputable University in Indonesia. His background was bachelor degree of Informatics Engineering (IT). He started his career not as IT Engineer but as Production Analyst of Paper Machine, he discovered and learned something new, production analysis, cost analysis, the whole process of paper making. After 2 years he moved to Condition Monitoring Section, he was given challenge to enter new career path, move forward, learn mechanical & rotating equipment and finally found his passion in Machine Condition Monitoring. In 2013 he passed Mobius Institute Vibration Analyst CAT I. He found that Mobius Institute Cristal Clear learning system was very helpful, easy to understand with many animations and interactive learning system. Then in 2016, He passed Mobius Institute Vibration Analyst CAT II with score 90-100% exam result. He also active as Vibration & Field Balancing Trainer in APP Academy. His recentachievement is Mill Best Employee 2018 for Supervisor category. His dream is to become professional in Condition Monitoring & Reliability.

Mr Mohammed,

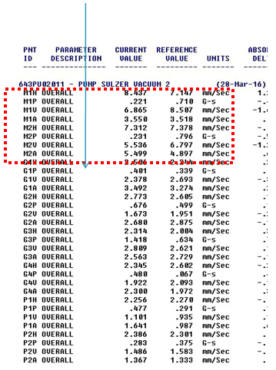

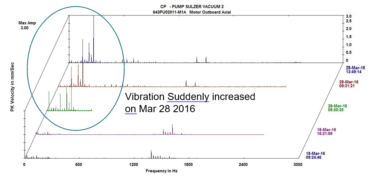

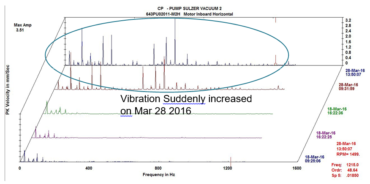

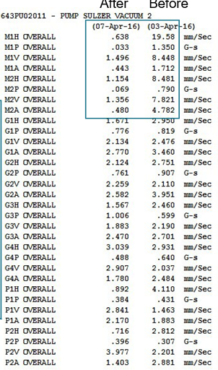

Like your analysis, sequence presentation in knowing the unknown frequencies.

Secondly, normally we get PPF, RBPF etc in many motors and also with additional inputs from MCSA. But identifying faults in rotor bars correctly need serious analysis involvement. Nice and all the best for your next predictions. Now there is a need to go for RCA.

nice one!

How many rotor bar is this motor? Did you see that freqeuncy?

NICE JOB Muhammad and good analysis

Hi all,

I have enjoyed the analysis and it certainly is a very sophisticated approach.

A couple of questions, and apologies in advance if they were staring me in the face the whole time but;

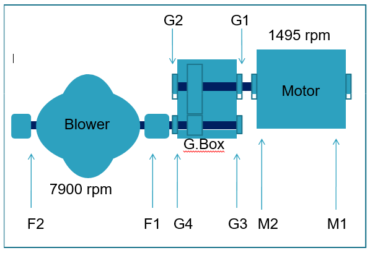

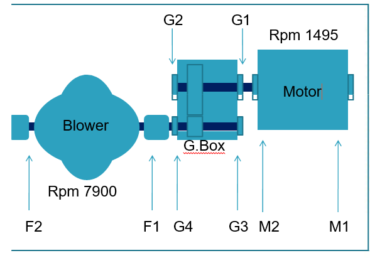

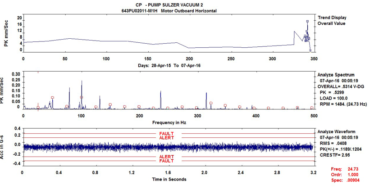

1) how was sync speed established at 1495RPM?

2) same for actual speed at 1488rpm? M1H run speed states 1503rpm

Thanks in advance. I am still new to VA but definitely willing to learn.

Thanks Mohammad…Your report is very helpful for me in recently facing a same issue.