Voltage Variation in AC Electric Motors

Now we’re going to discuss voltage testing. I’ve seen different variations of voltage testing on AC induction motors; however, the motor only really cares about the phase-to-phase voltage. So if I want to see if the voltage is having an effect on the operation of my machine, I need to go A to B, A to C, and B to C so that I end up with voltage readings across each phase. I can then take a look at two things. The first one would be voltage variance. They’re managed separately, so the voltage variance is ± 10% of the nameplate voltage, so in this case, in the United States, that would be 460 volts for this particular application. If it’s some other voltage, the same rules apply.

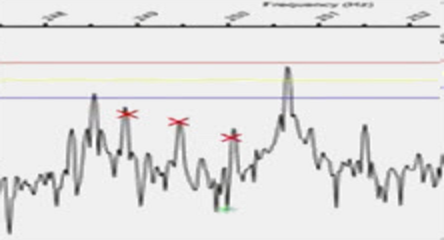

If the average voltage is 495 volts, and I say 495 minus 460, divided by 460, times 100%, that would be basically 7.6% voltage unbalance, and then I can see what the impact may be on my motor’s operation by taking a look at this chart (voltage variation chart). On this chart, which is an average of the impact of voltage variation, as you can see, it is 7.5% over voltage. My full-load amps will go up, my power factor will decrease, my efficiency will decrease, my starting current will also go up significantly, and my starting torque will go up. However, you should keep in mind that as I approach that ± 10%, the heating within the electric motor will go up, hence, the reduction in efficiency.

The other one is voltage unbalance. This is a very different measurement. In this case, I want to see what happens, because a voltage unbalance will cause significant current unbalance and it also may cause unbalanced magnetic fields, generating a counter-rotating torque on the rotor. That means that there is a heating de-rate that has to be considered. So let’s take this example. Again, that 460-volt motor, with the A-phase showing as 455, B-phase showing as 470, and C-phase showing as 473. I add them together and divide by 3, and I have 466 volts. If I take that 466 volts and subtract from the furthest away (455), divide by 466 and multiply by 100%, I have 2.3%. I can apply that, then, to a chart. This chart is the de-rating measurements from NEMA MG 1. So at about 2.5%, that would be about a .925 reduction. So that means if I had a 100-hp motor with a 2.5% voltage unbalance, in effect, that would be a 92.5-hp motor.

Thank you , Howard for this informative talk.