What is emissivity as it relates to infrared measurements? Emissivity is defined as the ratio of the energy radiated from a material’s surface to that radiated from a black body (a perfect emitter of infrared radiation) at the same temperature and wavelength and under the same viewing conditions. A value of 1 would be a perfect emitter. As you’ll see in a moment, emission is opposite to reflection, so if it was a value of 0, it would actually be a perfect reflector.

Emissivity is the inverse of reflectivity. For example, asphalt would have an emissivity value of 88%, or .88, and reflectivity of 12%, or .12, as it’s often reported. Aluminum foil, a very shiny surface, has very low emissivity (3%) and very high reflectivity (97%).

The emissivity of a material’s surface depends on many chemical and physical properties, and it is often difficult to estimate. One solution is to modify the emissivity, for example by coating the surface with high-emissivity black paint, or using tape, or roughing the surface to either provide a known emissivity value or improve emissivity.

Emissivity is very important because it determines what temperature we will read on our infrared camera. You can pause the video if you’d like and look at these values (table of metals and nonmetals with emissivity values). You can see the different materials, and it depends on whether it’s polished or not, or whether it’s oxidized, or rusted, or whatever, and you can see what the emissivity values are.

If you can tell the camera what the emissivity is, then it can give you a direct reading of the temperature. It can take the infrared radiation and convert it to a reasonably accurate temperature if you know exactly what the emissivity is. Otherwise, you’ll see that it looks hot or cold, but the actual reading you get will not be accurate.

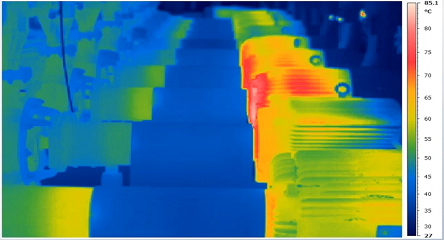

How does emissivity affect readings? Here is our perfect black body; it’s a perfect emitter (1.00). Here is oxidized copper, so the emissivity value is 68%, or .68, and here is polished copper (.02), so there’s oxidized copper vs. polished copper. Here’s my little simulator. I took a thermometer and put it against each one. Each of these rods is the same temperature. But when I use my infrared imaging camera and look at those temperatures, you can see that, from the infrared point of view, they appear to be different. Because this is a black body, and assuming my camera was set up accordingly, the temperature must be exactly 30°C/86°F. But because of the difference in emissivity, and that’s all, the oxidized copper is a bit more reflective—the black body isn’t reflective at all—it still does a good job emitting the heat but shows a temperature of 25°C/77°F. The polished copper shows a temperature of 20°C/68°F.

So here is a very common example used to explain these things: We’ve got an electric jug (with two pieces of tape on the silver). We boil water; it gets very, very hot. But when you use a thermal imaging camera, you can see here, where it’s shiny metal, it looks cold (violet). The two pieces of tape happen to have very good emissivity. If you were to measure the surface of the jug and the tape, it would all be the same temperature, so the tape is the same temperature as the metal surface. But from a thermal imaging point of view, it would show very different temperatures (taped area shows yellow-white).

Coating the surface you wish to test with special paint, or just electrical tape, is one solution to the problem, as I mentioned earlier. But again, it all depends on the surface of the tape you use. There are plenty of people who can help you choose the right materials, but it’s important to understand emissivity because, otherwise, it’s very easy to use an infrared camera, take a measurement, and think, goodness me that’s hot. There’s a problem here and we’d better do something about it. But it’s not actually hot at all.