What size particles do the most harm? I’m talking about contamination particles in hydraulic fluid and in the oil lubricating your machines.

What is it that we’re worried about? (I’m talking mostly about machines here rather than hydraulic equipment.) The particle shown in the raceway of this bearing looks pretty big, but that is just for animation purposes. Imagine, however, a small particle that gets trapped between the rolling element and the surface of the bearing. It gets indented into the raceway. It will pop out again, but it has created this tiny area of damage on the raceway and maybe on the rolling element as well.

As those rolling elements keep rolling over the damaged area, it will get bigger and bigger. So these small particles (we’ll talk about exactly how small they are in a moment) do a lot of damage and you’ve got to keep them out. It’s all about having clean oil, stopping those contaminants from getting in, and filtering the contaminants out when you need to.

This applies to hydraulic equipment and bearings, and also to gears. If there is a particle trapped in there, it will damage the teeth.

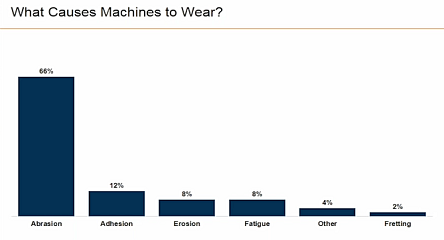

A study was performed some time ago (the references are shown in the video) on bearings within a gearbox (the clearances in a bearing are similar to a gearbox). They performed a test in which they started filtering the oil at about 40 microns and then filtered the oil at 25 microns.

What impact did that have? The y-axis shows the millions of cycles to failure—meaning how long it would take until failure occurred if they ran the machine in an accelerated way. With the 40-micron filter, it took a certain time (a little under 3.5 on the y-axis), and with the 25-micron filter, it took more time (around 4 on the y-axis). So we want to be further up the y-axis because that means the machine will go through more cycles before it fails.

There was not a significant difference between 40 and 25-micron filtration. With 10-micron filtration, it is better (about 5) but not fantastic. With 6-micron filtration and 3-micron filtration, however, we move up to 6 and 12 on the y-axis—that’s where the money is. You may want to filter 40, 20, and 10-micron particles, but it is better to filter down to 3-micron particles, that is, 3 microns and larger, because those do the most damage.

There are ways to avoid getting particles into the oil in the first place and filtering the oil out. There is a lot we could talk about there, but right now the emphasis is on the size of the particles that do the damage. I have heard people say, “Well, we’ve tried filtering it out down to 3 microns, but it was costing us a lot because there were so many particles going through filter media.” This is crazy talk in a way. Would you rather have machine failures or spend a bit more on filters?

It’s the really small particles that do the damage. One way to think about it is to refer back to the animation of the bearing. The gap between the rolling elements and the raceway is about 1 micron. It may be even smaller than that. That’s the same sort of clearance seen in a gearbox. The oil is the only thing holding those two surfaces apart—that’s why the lubricant is so important. Again, that’s the case with gears and with rolling elements.

So imagine if you put a 40-micron particle in there. Is that going to get jammed between the rolling elements and the raceway, or is it going to just get pushed out the way? It could harm the machine by scoring the surface, and it could harm the bearing or gear. But it’s really the small particles that are likely to get in between the rolling elements and the raceway and get pushed down hard into the raceway or the rolling element itself. That’s why we are worried about them and not the big particles.